Top 10 Packer Machine Models for Efficient Packaging Solutions

In the ever-evolving packaging industry, the significance of a reliable packer machine cannot be overstated. Industry expert, Dr. Emily Carter, once stated, “The right packer machine can transform efficiency and productivity.” This sentiment resonates deeply among packaging professionals striving for excellence in their operations.

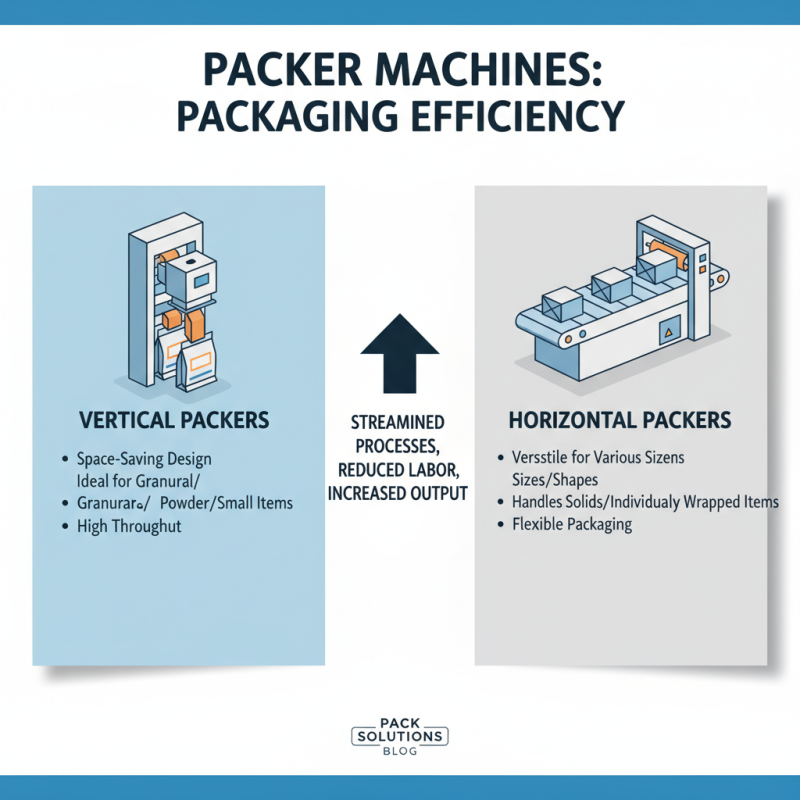

Packer machines play a crucial role in ensuring products are packaged accurately and quickly. They streamline the traditional processes and reduce labor costs, but not all models are created equal. Each model comes with its own set of advantages and limitations. A careful examination is necessary to identify what fits best for a specific production line.

Despite advancements, many businesses still grapple with outdated equipment. Their struggles highlight the importance of investing in modern solutions. Inadequate packing solutions can lead to delays and increased waste. Therefore, understanding the top 10 packer machine models can guide companies toward smarter investments. The right choice can significantly influence overall operational efficiency.

Overview of Packer Machine Models in the Packaging Industry

In the fast-paced world of packaging, efficiency is key. Packer machines have revolutionized how products are packaged across various industries. These machines streamline processes, reducing labor costs and increasing output. Among them, vertical and horizontal models serve different needs, accommodating a range of products. Vertical packers are often favored for their space-saving designs. Horizontal machines excel in versatility, able to handle various package sizes.

Understanding the specific functions of each model is crucial for selecting the right one. For instance, some machines are designed for fluid products, while others cater to solids. This diversity can create confusion. Businesses must evaluate their unique requirements before investing in a packer machine. Moreover, maintenance and training can be overlooked aspects, leading to inefficiencies. A machine may be top-of-the-line, but without proper knowledge or upkeep, productivity can falter.

Integrating new technologies can further enhance performance. However, companies should proceed cautiously. New features sometimes come with a learning curve. This adjustment period can disrupt operations if not managed well. Balancing innovation with practicality remains a significant challenge in choosing the right packer machine. Ultimately, the goal is to find solutions that simplify the packaging process while minimizing errors and maximizing efficiency.

Key Features to Consider When Selecting Packer Machines

When selecting a packer machine, key features play a crucial role. Efficiency is vital. Look for machines that can handle multiple products. Speed is another important aspect. The right machine can significantly reduce bottlenecks in your production line. A machine that operates smoothly saves time and costs.

Ease of use is also essential. Operators should find the controls intuitive and straightforward. It minimizes training time, improving productivity. Maintenance is critical too. Choose models that are easy to clean and maintain. Frequent breakdowns can affect output.

Consider the versatility of the machine. A model that can adapt to different packaging needs is beneficial. For example, if it can handle various shapes and sizes, it enhances flexibility. However, not all machines are created equal. Some may excel in one area but fall short in others. Regular reviews of machine performance are necessary for ongoing efficiency.

Top 10 Packer Machine Models for Efficient Packaging Solutions

This chart displays the efficiency scores of the top 10 packer machine models, providing a visual representation of their performance. A higher score indicates a more efficient packaging solution.

Comparison of Top 10 Packer Machine Models for Various Needs

When choosing a packing machine, different models cater to various needs. Some machines excel in speed, while others focus on precision. Understanding your requirements is key to selecting the right model. For instance, if your product varies in size, a flexible machine is essential. Machines that adjust their settings quickly can save time and materials.

Here are a few tips: Think about your product type. Fragile items need careful handling. For heavier products, ensure the machine can support the weight. It's also wise to consider the space you have. Some machines are compact, while others require more room.

You might face challenges during setup. Not every model is user-friendly. Training staff can take time. Plan for potential downtime in your operations during this phase. Investing in user-friendly technology could pay off in the long run. Make a checklist to compare features before making a decision. Always revisit your choices, as packing needs may change over time.

Innovations and Trends in Packer Machine Technology

The packaging industry is rapidly evolving. Recent reports estimate that the global packaging machinery market will exceed $50 billion by 2025, driven by technological innovations. Smart packer machines are at the forefront of this change, enhancing efficiency and reliability. These machines utilize smart sensors and AI to streamline operations. This tech integration helps reduce downtime and improves accuracy.

One notable trend is the rise of sustainable packaging solutions. Companies now seek machines that minimize waste and utilize eco-friendly materials. The demand for such equipment has surged, reflecting a broader commitment to sustainability. A study shows that nearly 70% of consumers prefer brands focused on environmental initiatives. However, not all packaging technologies are fully sustainable yet. Some solutions still leave room for improvement.

Training operators on advanced machinery can be challenging. Misoperation can lead to increased costs and inefficiencies. The technology must also be user-friendly. Many manufacturers face dilemmas in balancing high technology with ease of use. As the industry moves forward, addressing these issues remains vital for achieving true efficiency in packing solutions.

Best Practices for Maintaining Packer Machines for Optimal Efficiency

Efficient maintenance of packer machines is essential for productivity in modern packaging operations. A study by the Packaging Machinery Manufacturers Institute (PMMI) shows that regular maintenance can boost machinery lifespan by up to 30%. Neglecting maintenance can lead to downtime and increased operational costs. Keeping machines clean and well-lubricated enhances performance and decreases the risk of breakdowns.

Tips: Establish a daily inspection routine. Check for wear and tear. Minor issues can escalate if ignored.

Regularly update software systems. This ensures your machinery runs smoothly and adapts to new packaging requirements. A 2022 report highlights that over 25% of packer machine failures arise from outdated software. Operators should stay informed about the latest advancements.

Tips: Train staff regularly. Knowledgeable operators spot problems early. A well-trained team is an asset.

Stay vigilant about your production schedules. Unexpected downtime can disrupt operations. Scheduling maintenance during off-peak hours can mitigate risks. It’s important to balance efficiency with thorough inspections. Striving for perfection may lead to overlooking critical issues. Always reflect on your practices and seek areas for improvement.

Top 10 Packer Machine Models for Efficient Packaging Solutions

| Model | Type | Speed (packages/min) | Dimensions (L x W x H) mm | Weight (kg) | Energy Consumption (kW) |

|---|---|---|---|---|---|

| Model A | Vertical | 120 | 1500 x 800 x 2000 | 500 | 3.5 |

| Model B | Horizontal | 150 | 1800 x 900 x 2100 | 600 | 4.0 |

| Model C | Semi-Automatic | 100 | 1600 x 850 x 1900 | 450 | 2.5 |

| Model D | Fully Automatic | 200 | 2000 x 1000 x 2200 | 700 | 5.0 |

| Model E | Wrap-around | 90 | 1700 x 800 x 2050 | 500 | 3.0 |

| Model F | Case Sealing | 110 | 1950 x 850 x 2100 | 600 | 4.2 |

| Model G | Strapping | 80 | 1600 x 750 x 1800 | 470 | 2.8 |

| Model H | Filling | 160 | 1750 x 900 x 2000 | 540 | 3.3 |

| Model I | Palletizing | 70 | 2050 x 1200 x 2300 | 800 | 6.5 |

| Model J | Sleeve Wrapper | 130 | 1900 x 950 x 2150 | 590 | 4.0 |

Related Posts

-

7 Essential Tips for Optimizing Packaging Systems: Boost Efficiency by 30%!

-

10 Best Packet Machines for Efficient Packaging Solutions

-

Top 10 Packer Machines: Best Choices for Efficient Packaging Solutions in 2023

-

How to Choose the Right Case Packer Machine for Your Packaging Needs

-

10 Best Tips for Effective Packaging Design to Enhance Your Brand Appeal

-

Why Industrial Packaging is Essential for Business Efficiency and Sustainability