Top Packaging Equipment Systems for Efficient Production?

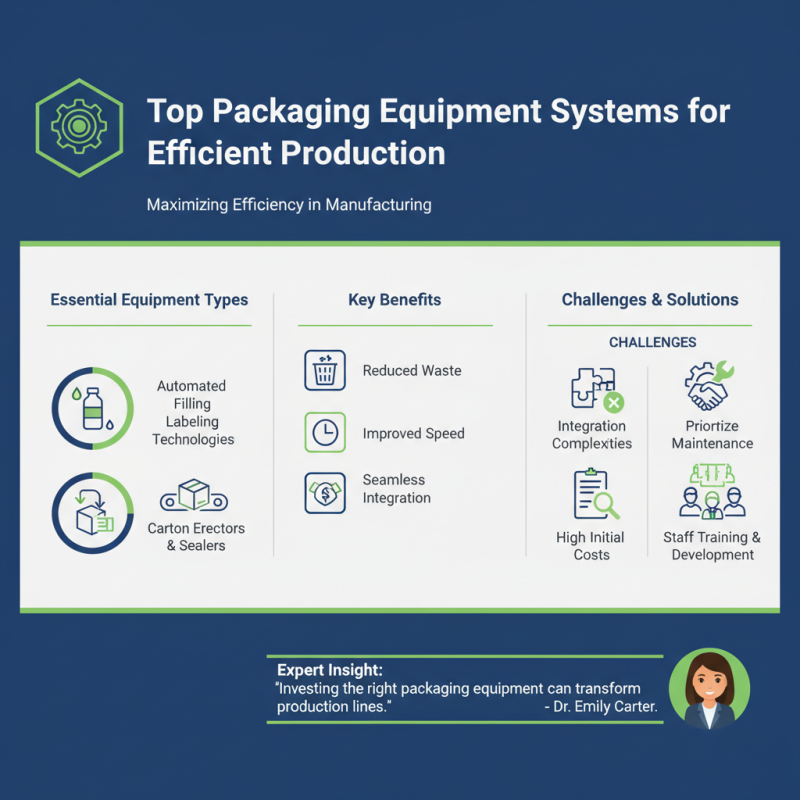

In the fast-paced world of manufacturing, maximizing efficiency is vital. Leading expert in packaging equipment systems, Dr. Emily Carter, states, "Investing in the right packaging equipment can transform production lines." Her insight highlights the importance of selecting effective solutions for modern production needs.

Packaging equipment systems have evolved significantly. From automated filling machines to advanced labeling technologies, these systems are essential in reducing waste and improving speed. With growing demands, manufacturers must adapt quickly. However, integration challenges and high costs can complicate the decision-making process.

Many companies overlook maintenance and training. Neglecting these areas can lead to suboptimal performance. As Dr. Carter warns, "Even the best systems fail without proper use." Ensuring staff is well-trained enhances the capability of packaging systems. Thus, while the technology can propel production, human oversight remains crucial for success.

Top Trends in Packaging Equipment for Enhanced Production Efficiency

In today's fast-paced production environment, packaging equipment plays a vital role. Automation has emerged as a key trend. This reduces manual labor and speeds up the packaging process significantly. Many companies are investing heavily in automated systems. These systems often come with sophisticated sensors and software. They help in monitoring quality in real-time.

Another prominent trend is sustainability. Many producers are seeking eco-friendly materials. This shift not only meets consumer demand but also aligns with environmental goals. However, finding sustainable options that do not compromise on efficiency can be challenging. Packaging equipment needs to adapt to these new materials. This creates an ongoing challenge for manufacturers.

Moreover, customization is gaining traction. Clients desire packaging tailored to their specific needs. This requires flexible machinery capable of quick changes. Yet, managing such versatility often leads to inefficiencies. Balancing customization with production speed is crucial. Companies are realizing that focusing on one aspect sometimes hampers overall efficiency. Continuous reflection on these issues is necessary for improvement.

Top Trends in Packaging Equipment for Enhanced Production Efficiency

This chart illustrates the efficiency improvements brought by various packaging equipment systems in the production process. The data showcases the percentage increase in production efficiency by adopting advanced packaging technologies.

Key Metrics for Evaluating Packaging Systems in Manufacturing

When evaluating packaging systems in manufacturing, several key metrics come into play. Efficiency is crucial. According to recent industry reports, systems that streamline packaging workflows can lead to a 30% reduction in production time. This efficiency is often measured in output rates and downtime. Understanding these metrics is essential for decision-making.

Cost is another vital statistic. Businesses should calculate the total cost of ownership (TCO) for each system. This includes initial purchase, maintenance, and operational expenses. Some reports indicate that investing in automated systems can lead to cost savings of up to 20% over five years. However, this requires upfront investment knowledge.

Tip: Always conduct a thorough return on investment (ROI) analysis. This helps in justifying expenditures on new equipment. Additionally, consider flexibility. Systems that adapt to various packaging needs often provide better long-term value.

Quality control metrics should not be overlooked. Systems often suffer from occasional faults, leading to waste or rework. In a recent survey, 15% of manufacturers reported issues with system inconsistencies. Continuously monitoring these factors is essential for sustainable production.

Innovative Technologies Driving the Future of Packaging Automation

Innovative technologies are transforming packaging automation. The global packaging machinery market is projected to reach $50 billion by 2026, driven by efficiency and productivity gains. Automation plays a crucial role in this growth. Smart systems reduce manual labor and errors. They also streamline operations, enhancing output rates.

One significant advancement is IoT integration. Internet-connected devices offer real-time data. This enhances decision-making in the production line. AI-based systems optimize packaging processes. They analyze trends to anticipate issues before they become problems. Companies report a 10-30% increase in efficiency with these technologies.

Tips: Evaluate your current systems. Identify areas that could benefit from automation. Implementation can be daunting, but starting small can yield significant results. Engage your team in the transition. Their feedback is vital for a successful upgrade. Continuous learning will help adapt to new trends. Ensure your team is equipped for future challenges.

Top Packaging Equipment Systems for Efficient Production

| System Type | Key Features | Efficiency Improvement (%) | Adoption Rate (%) | Cost ($) |

|---|---|---|---|---|

| Automated Filling | Precision filling, fast cycle times | 30 | 70 | 15,000 |

| Labeling System | High-speed labeling, adaptable formats | 25 | 65 | 10,500 |

| Robotic Palletizing | Flexibility, reduced labor costs | 40 | 50 | 45,000 |

| Cartoning Machine | Speed and efficiency, customizable | 35 | 60 | 25,000 |

| Shrink Wrapping | Durability, compact packaging | 20 | 55 | 8,000 |

Comparative Analysis of Packaging Equipment for Diverse Industries

In the world of production, packaging equipment plays a crucial role. Different industries require various types of machinery to meet their specific needs. For instance, the food sector often uses heat sealers or vacuum packagers to extend shelf life. In contrast, cosmetics may utilize airless pumps and flexible pouches. Each system has its advantages and limitations.

When assessing packaging systems, consider efficiency and versatility. Some machinery may excel in one area but fail in another. It’s important to analyze workflow and product type. If a company lacks flexibility in their equipment, it could result in increased downtime. Evaluate your production line. Is your equipment adaptable for different runs?

Tips: Regularly train your team on maintenance. This reduces breakdowns. Consider investing in modular systems. They often provide better scalability. Also, analyze data on production cycles. Sometimes, what works best on paper may not translate well during actual production. Keep an eye on emerging technologies. They can offer innovative solutions for your industry needs.

Case Studies: Successful Implementations of Efficient Packaging Solutions

In various industries, efficiency in packaging is crucial. Many businesses have implemented innovative systems to optimize their production processes. One example involved a food manufacturing plant. They upgraded their packaging line with automated machines. This change streamlined their workflow and reduced labor costs. However, it took time to train the staff on the new technology. Some initial errors in packaging prompted a reassessment of their processes.

Another case study highlights a cosmetic company that transitioned to sustainable packaging. They invested in eco-friendly materials and modern machinery. This decision not only improved their brand image but also attracted a new customer base. Yet, they faced challenges in sourcing these materials. Delays in supply chains affected their production schedules. This scenario showcased the need for adaptability in their operations.

These examples illustrate the balance required in adopting new packaging solutions. Efficiency and environmental concerns need to correspond. While the implementation of new systems can enhance productivity, ongoing challenges remain. Continuous evaluation and feedback are essential to navigate these transitions effectively.

Related Posts

-

How to Choose the Right Packaging Equipment for Your Business Needs

-

10 Best Packet Machines for Efficient Packaging Solutions

-

Top 10 Packaging Automation Equipment Trends for 2023 You Need to Know

-

2025 How to Choose the Best Packaging Machine for Your Business Needs

-

Top 10 Wrapping Machines to Boost Your Packaging Efficiency in 2023

-

How to Choose the Right Packaging Machine for Your Business Needs