2026 How to Choose the Best Wrapping Machine for Your Business Needs?

Choosing the right wrapping machine is crucial for any business. According to industry expert John Smith, "The right wrapping machine can enhance efficiency and reduce waste." Understanding your specific needs is essential. Every business has unique requirements based on the products they handle and their production processes.

Consider the type of items you will be wrapping. A machine suited for small items may not serve larger products well. Moreover, speed and dimensions are important factors. Not all wrapping machines can accommodate varying sizes efficiently.

Investing in an inadequately chosen machine can result in frustration. What seems like a cost-effective choice may lead to operational delays. Reflecting on past experiences may help. Analyze the features that truly matter. A well-considered decision will ultimately benefit your business in the long run.

Identifying Your Business's Packaging Requirements

Identifying your business's packaging requirements is crucial for effective operations. Start by analyzing the products you offer. Are they fragile, bulky, or perishable? Different items require different packaging solutions. For instance, a small electronics company may need anti-static packaging, while a bakery may focus on breathability.

Consider the volume of products you package. A high-output business may require faster machines, while a smaller operation could manage with a simpler model. Think about your budget too. Sometimes, you might overspend on features you don’t truly need. Reflect on past packaging experiences. Did issues arise with your previous machines? Pinpointing failures can guide your future choices.

Look into environmental factors as well. Sustainable packaging options are growing in importance. While you want to stay budget-friendly, eco-friendly choices can enhance your brand image. However, this doesn't always mean they are cost-effective. Carefully evaluate if the benefits justify the cost. Balancing practicality and sustainability can be challenging.

Understanding Different Types of Wrapping Machines

When selecting a wrapping machine, understanding the different types is essential. There are several kinds, each designed for specific needs. First, there's the manual wrap machine. It requires human effort but is cost-effective and easy to use. Ideal for small businesses, it offers flexibility but can be labor-intensive.

Next, consider semi-automatic wrapping machines. These machines streamline the wrapping process, combining manual and automatic features. They increase productivity but may come with a learning curve. Businesses might face issues during setup. Proper training is vital here.

Automatic wrapping machines represent the pinnacle of efficiency. They can wrap products quickly with minimal supervision. However, they require a higher investment. This high cost might not justify their use in smaller operations. Ultimately, each option has advantages and drawbacks. Evaluating your business's specific needs will lead to better choices.

2026 How to Choose the Best Wrapping Machine for Your Business Needs? - Understanding Different Types of Wrapping Machines

| Machine Type | Best For | Price Range | Speed (Packages/Hour) | Power Requirement |

|---|---|---|---|---|

| Semi-Automatic Wrapping Machine | Small to Medium Businesses | $2,000 - $5,000 | 30 - 50 | 220V |

| Fully Automatic Wrapping Machine | Large Scale Production | $10,000 - $50,000 | 100 - 200 | 380V |

| Shrink Wrapping Machine | Products That Require Protection | $3,000 - $15,000 | 20 - 80 | 220V or 380V |

| Horizontal Wrapper | Confectionery and Bakery Products | $5,000 - $25,000 | 50 - 150 | 220V |

| Vertical Wrapper | Pouches and Bags | $4,000 - $20,000 | 40 - 120 | 220V |

Evaluating Key Features of Wrapping Machines

When evaluating wrapping machines, several key features stand out. First, look at speed and efficiency. According to industry reports, high-speed machines can process up to 150 packages per minute. This high throughput can significantly boost productivity. However, speed shouldn't compromise quality. A poorly wrapped product can lead to damage during transit. Finding a balance is crucial.

Next, consider the machine's versatility. Many businesses require different types of wrapping. Some might need stretch film, while others prefer shrink wrap. A flexible machine can adapt to various materials and sizes. This adaptability often results in cost savings. Yet, it is essential to assess how easy it is to switch between materials. A complex setup can waste valuable time.

Another important feature is the ease of operation. User-friendly controls can minimize training time for staff. Studies indicate that machines with intuitive interfaces can reduce error rates by up to 25%. Still, a simple design must not compromise functionality. Regular maintenance is also vital; this can often be overlooked. Neglecting machine upkeep can lead to costly downtimes. Assessing these features can guide you towards the right decision.

Assessing Budget and Cost Efficiency

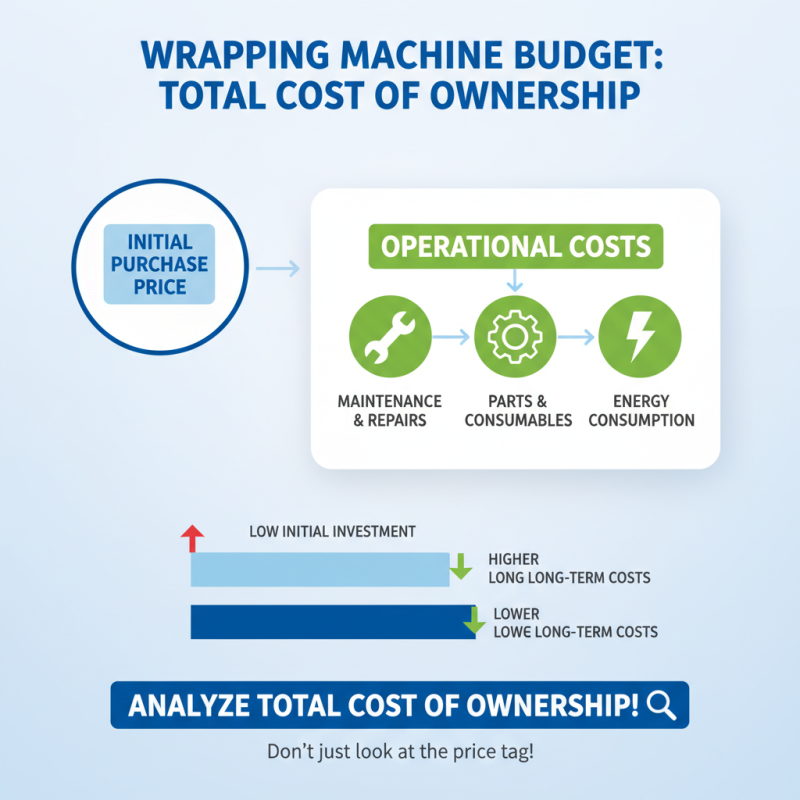

When evaluating budgets for a wrapping machine, it’s essential to consider both purchase price and operational costs. A lower initial investment can be appealing. However, it might lead to higher maintenance costs later. Always analyze the total cost of ownership. This includes repairs, parts, and energy consumption over time. Estimating these factors can sometimes be challenging.

Understanding your production volume is crucial too. A machine that works well for small batches may underperform in larger settings. Conversely, overspending on an industrial model for low demand can strain finances. It's a balance that requires careful thought. Comparing features can be overwhelming. Assessing which features add real value is necessary for budget efficiency.

Consider potential future needs as well. If your business expands, will the machine still meet requirements? Planning for growth might mean spending a bit more now. This foresight can save money in the long run. Budgeting is a dynamic process. Regularly revisiting your financial strategy is wise. This allows adjustments as industry standards and your needs evolve.

Researching Manufacturers and Reviews for Informed Choices

When selecting a wrapping machine, thorough research is crucial. Investigating manufacturers helps you understand different types and features. Look for producers with a solid reputation. Reviews can reveal the actual performance of machines. Read multiple sources to get a comprehensive view. Customer feedback often highlights strengths and weaknesses. Some machines may have issues that aren't immediately obvious.

Consider joining online forums and communities. Users often share their experiences with various machines. This feedback can guide you in your decision-making process. It’s essential to ask questions and seek advice. Some machines might have hidden costs like maintenance and parts. This information can be valuable when planning your budget.

Alongside reviews, take time to assess workflow requirements. The best machine for your business should fit your specific needs. Sometimes, higher efficiency does not equate to better performance. A more complex machine may be unnecessarily burdensome. Reflect on your capacity for training staff on new equipment. Balancing productivity with user-friendliness is key.

2026 Wrapping Machine Satisfaction Ratings

This chart displays the satisfaction ratings of various wrapping machine features based on user feedback in 2026. The data highlights the importance of reliability, efficiency, and ease of use in selecting a wrapping machine for business needs.

Related Posts

-

Top 10 Wrapping Machines to Boost Your Packaging Efficiency in 2023

-

10 Best Packet Machines for Efficient Packaging Solutions

-

How to Choose the Right Packaging Equipment for Your Business Needs

-

How to Choose the Right Packaging Machine for Your Business Needs

-

Top 10 Packaging Automation Equipment Trends for 2023 You Need to Know

-

2026 Best Automated Packaging Machines for Efficient Packaging Solutions?