2025 How to Choose the Best Packaging Machine for Your Business Needs

In the rapidly evolving world of manufacturing and distribution, the selection of the right packaging machine is vital for the success of your business. A packaging machine not only enhances the efficiency of the packing process but also plays a significant role in maintaining product quality and safety. With various options available on the market, it can often be overwhelming to determine which packaging machine best meets your specific operational needs.

Understanding the different types of packaging machines and their functionalities is essential for making an informed decision. Factors such as production volume, type of products, and packaging materials all influence which machine will be the most effective for your operations. Additionally, considering the potential for scalability and flexibility in equipment can help ensure that your investment supports your business growth in the long term. By thoroughly assessing these aspects, you can choose a packaging machine that not only streamlines your processes but also aligns with your overall business strategy.

Understanding Your Packaging Requirements for 2025

To select the best packaging machine for your business in 2025, it is crucial to understand your specific packaging requirements. Start by assessing the type of products you intend to package, as this influences the machinery and materials needed. Consider factors such as the size, shape, and fragility of your products, as well as the desired packaging style—whether it’s shrink-wrapping, bottling, or bagging. Understanding these aspects will help you narrow down your options and focus on machines that cater to your unique needs.

Additionally, evaluate your production volume and workflow. Determine how fast you need to package your products, as this will dictate the speed and efficiency of the machine you choose. A thorough analysis of your production line will also help identify if you need a standalone machine or a more integrated solution that works seamlessly with your existing systems. Take into consideration the versatility and scalability of the equipment, ensuring it can adapt to potential changes in demand or product offerings over time. This strategic approach will ensure you select a packaging machine that aligns well with your business goals for 2025 and beyond.

2025 How to Choose the Best Packaging Machine for Your Business Needs - Understanding Your Packaging Requirements for 2025

| Packaging Type | Machine Features | Production Speed (units/hour) | Cost Range ($) | Ideal For |

|---|---|---|---|---|

| Shrink Wrapping | Automatic, adjustable temperature | 50-100 | 5,000 - 15,000 | Food, Electronics |

| Box Sealing | Automatic, hot melt adhesive | 30-80 | 3,000 - 10,000 | E-commerce, Retail |

| Filling | Multi-head, adjustable volume | 20-60 | 10,000 - 30,000 | Beverages, Chemicals |

| Labeling | Automatic, high-speed applicator | 100-200 | 5,000 - 12,000 | Food, Cosmetics |

| Palleting | Robotic, adjustable configurations | 10-30 | 15,000 - 40,000 | Warehousing, Distribution |

Evaluating Different Types of Packaging Machines

When evaluating different types of packaging machines, it’s essential to consider the specific needs of your business. The first step is to identify the nature of the products you will be packaging. For instance, bulk items may require a different solution than fragile goods or liquids. In this context, vertical form-fill-seal machines could be ideal for powders and granules, while horizontal machines may work better for larger or irregularly shaped items. Understanding the product characteristics helps in selecting a machine that optimally balances efficiency and protection.

Another critical factor in choosing the right packaging machine is the production volume. This influences the type of machine needed—whether a semi-automatic or fully automatic system is more suitable. High-volume operations often benefit from automation, which enhances speed and reduces labor costs. Additionally, consider the scalability of the packaging line. As your business expands, the ability to adapt or upgrade machinery will be vital. Evaluating the flexibility of the machine to accommodate various packaging formats and sizes can also add significant value to your operations, allowing for faster response to market demands.

Key Features to Look for in a Packaging Machine

When selecting a packaging machine that aligns with your business needs, it is essential to focus on several key features that will enhance efficiency and productivity. One important aspect to consider is the machine's versatility. A multi-functional packaging machine can handle a variety of products and formats, allowing your business to adapt to changing market demands without the need for constant equipment upgrades. This flexibility can save time and reduce costs in the long run.

Another critical feature is ease of use. A user-friendly interface, along with clear operation guidelines, can minimize training times and reduce the likelihood of operator errors. This becomes particularly important when scaling your operations or onboarding new staff. Moreover, ensure the machine offers quick setup and changeover times, enabling your production line to maintain a steady flow without unnecessary delays.

Tips: Always assess the maintenance requirements of the packaging machine you choose. Opt for machines with lower maintenance needs, as they can help avoid costly downtime. Additionally, consider energy efficiency and sustainability features, as they not only lower operational costs but also contribute positively to your brand’s environmental footprint. Investing in technology that enhances automation can also lead to significant productivity improvements, making your packaging process smoother and more efficient.

2025 Packaging Machine Feature Comparison

This chart compares the importance of various features in packaging machines based on potential business needs for 2025, highlighting key areas for consideration.

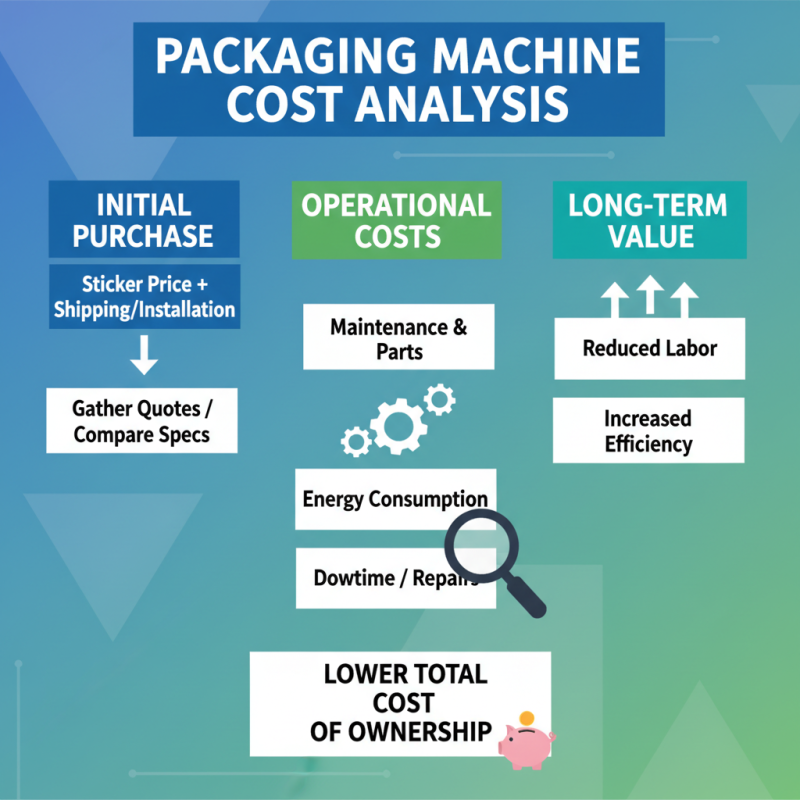

Cost Analysis and Budget Considerations for Packaging Equipment

When selecting the right packaging machine for your business, cost analysis is a critical step that can significantly impact your overall budget. First, consider the initial purchase price of the equipment. It's essential to evaluate not only the sticker price but also the long-term operational costs associated with maintenance, energy consumption, and potential downtime. A more expensive machine may have advanced technologies that reduce labor costs and increase efficiency, thus leading to lower overall costs in the long run. Gathering quotes and comparing specifications across different machines will help you make an informed decision.

Another key aspect of budget considerations is the potential return on investment (ROI). Analyze how the new packaging solution will affect your production speed, product quality, and labor requirements. A machine that increases your output or enhances your product's appeal could lead to higher sales and improved profit margins. Additionally, take into account any financing options or payment plans offered by suppliers, which can help alleviate upfront financial burdens. It's crucial to align your packaging machinery choice with your business growth strategy while ensuring that the cost fits comfortably within your operational budget.

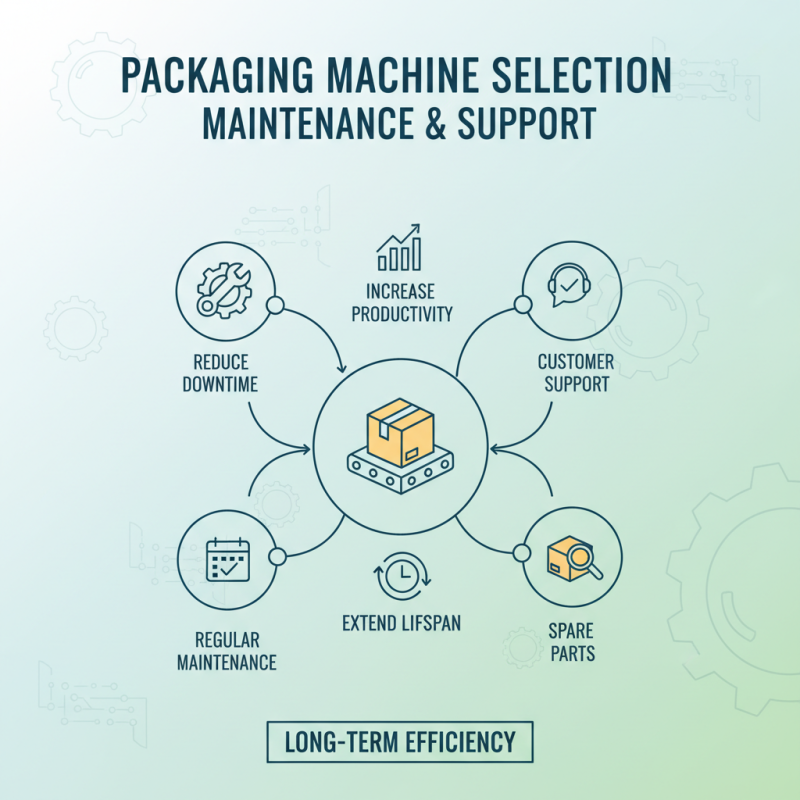

Maintenance and Support Options for Long-Term Use

When selecting a packaging machine, maintenance and support options play a crucial role in ensuring long-term efficiency and reliability. A well-maintained machine can significantly reduce downtime, increase productivity, and extend the machine's lifespan. Therefore, it's essential to consider the availability of service contracts and the reputation of the manufacturer regarding their customer support. Regular maintenance schedules should be outlined, and it's advisable to inquire about how easily spare parts can be sourced.

Tips: Always ask for a detailed maintenance plan before purchasing any packaging machinery. A proactive maintenance schedule can help identify issues before they escalate into costly repairs. In addition, check if the manufacturer provides training for your staff to handle basic troubleshooting and minor maintenance tasks, which can further minimize disruptions.

Another vital aspect is the accessibility of technical support. Look for providers that offer 24/7 support options, as this can be essential during unexpected machine failures. Additionally, consider whether they have local service teams that can respond promptly to your needs. Creating a partnership with a supplier who prioritizes ongoing support will ensure that your packaging operations run smoothly and efficiently over time.

Tips: Evaluate how response times vary among suppliers. Quick support can translate to less downtime for your production line. Moreover, ascertain whether they offer remote support capabilities, which can aid in diagnosing problems without lengthy wait times for a technician's visit.

Related Posts

-

How to Choose the Right Packaging Equipment for Your Business Needs

-

2025 How to Choose the Best Packaging Machine for Your Business Needs

-

How to Choose the Right Case Packer Machine for Your Packaging Needs

-

7 Essential Tips for Optimizing Packaging Systems: Boost Efficiency by 30%!

-

2025 Guide: How to Choose the Best Pouching Machine for Your Needs

-

How to Choose the Right Packaging Machine for Your Business Needs