How to Choose the Right Packaging Machine for Your Business Needs

Choosing the right packaging machine for your business is a crucial decision that can significantly impact your operational efficiency and product presentation. As John Smith, a renowned expert in the packaging industry, emphasizes, "The right packaging machine not only enhances product protection but also boosts the overall productivity of your production line." With the myriad of options available in the market, it can often be overwhelming for business owners to identify which machine aligns best with their specific needs.

When evaluating packaging machines, it’s essential to consider several factors, including production speed, machine versatility, and the nature of the product being packaged. Each business has unique requirements; therefore, a one-size-fits-all approach is rarely effective. Investing in a packaging machine that complements your operations can lead to improved efficiency, reduced labor costs, and ultimately, increased profitability.

In this article, we will explore the key considerations and steps you should take when selecting packaging machines tailored to your business needs. Whether you're a startup or an established enterprise, understanding these fundamental aspects will empower you to make informed decisions that align with your production goals.

Understanding Your Specific Packaging Requirements

When selecting the right packaging machine for your business, understanding your specific packaging requirements is crucial. According to a recent report by PMMI, the Association for Packaging and Processing Technologies, nearly 69% of companies cite efficiency as a primary driver in their packaging decisions. Therefore, it's vital to assess the nature of your products – whether they are fragile items requiring careful handling or bulk products that need fast and efficient packaging. Identifying these characteristics will help narrow down choices and optimize machine selection.

In addition to product types, consider the packaging volume and speed. Industry data indicates that businesses with high output needs (over 100 units per minute) often benefit from automated solutions. For instance, companies in the food and beverage sector face stringent regulations and require machines that can handle variations in packaging sizes while maintaining compliance. An insightful analysis by Allied Market Research projected that the demand for automation in packaging is expected to grow at a CAGR of 5.1% from 2021 to 2028, emphasizing the importance of investing in machines that can scale with your operations and meet technological advancements. By aligning your packaging machine choice with your specific operational requirements, you ensure efficiency and compliance, ultimately enhancing your overall productivity.

How to Choose the Right Packaging Machine for Your Business Needs - Understanding Your Specific Packaging Requirements

| Packaging Type | Machine Type | Production Speed (units/hour) | Cost ($) | Suitable for (Industries) |

|---|---|---|---|---|

| Bottles | Automatic Filling Machine | 1200 | 25,000 | Beverage, Chemical |

| Pouches | Vertical Form Fill Seal (VFFS) | 800 | 20,000 | Food, Snacks |

| Boxes | Cartoning Machine | 400 | 30,000 | Pharmaceutical, Cosmetics |

| Trays | Tray Sealing Machine | 600 | 15,000 | Ready Meals, Fresh Foods |

| Labeling | Labeling Machine | 1000 | 10,000 | All Industries |

Evaluating Different Types of Packaging Machines Available

When evaluating different types of packaging machines available on the market, it's essential to consider the specific requirements of your business. The primary types of packaging machines include horizontal flow wrappers, vertical form-fill-seal machines, and automatic case packers, each designed for distinct packaging needs. Horizontal flow wrappers are ideal for products that require a sealed wrap and are often used for snacks or baked goods. In contrast, vertical form-fill-seal machines are perfect for packaging powders, granules, or liquids, as they efficiently create pouches from film rolls.

Another critical aspect to consider is the machine's automation level. Manual and semi-automatic machines may initially seem cost-effective, but for businesses projecting growth or high-volume production, fully automatic solutions can enhance efficiency and reduce labor costs. Additionally, it's important to assess the machine’s adaptability to accommodate various products and packaging materials. An ideal packaging machine should be versatile enough to handle different shapes and sizes, ensuring that your packaging is both appealing and functional. Thus, a thorough evaluation of your packaging needs alongside the available machine functionalities will lead to a more informed purchasing decision.

Assessing Production Capacity and Speed Needs

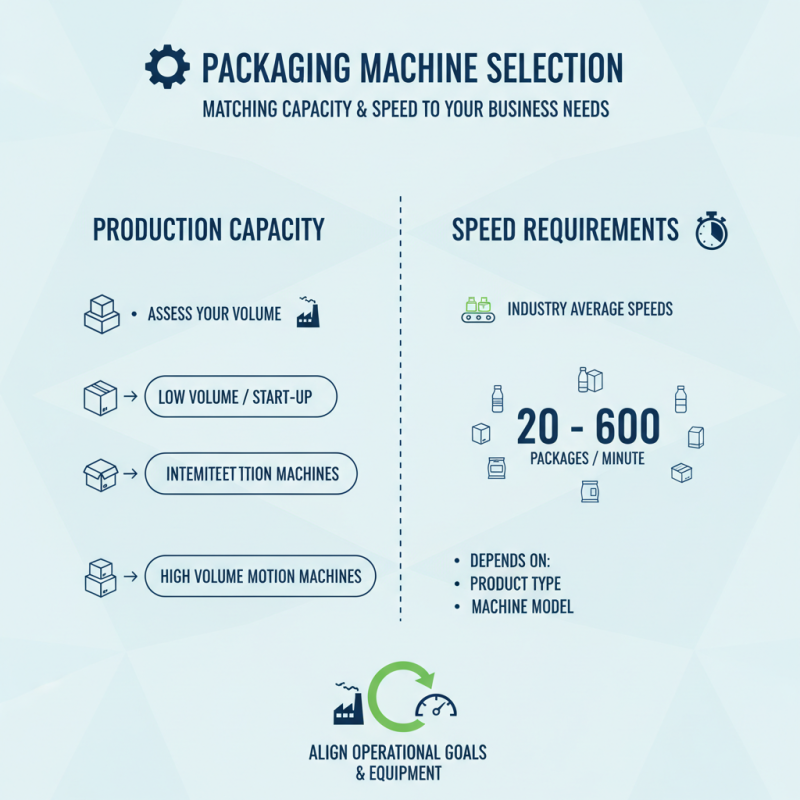

When selecting a packaging machine for your business, it is crucial to assess your production capacity and speed needs. According to industry reports, an average packaging line can achieve speeds from 20 to 600 packages per minute, depending on the product type and machine model. Understanding these metrics allows businesses to align their operational goals with the right equipment. For instance, a high-speed operation may require a continuous motion machine, while lower volumes can be adequately served by intermittent ones.

Tips: When evaluating your production needs, consider conducting a thorough analysis of your current output and future growth projections. This data will help identify whether you need a machine capable of handling peak demands or one that can efficiently manage daily operations.

Moreover, speed alone isn't enough; the machine's changeover time, durability, and adaptability to diverse packaging formats can significantly influence your productivity. A study highlighted that companies with machines allowing faster changeovers could reduce downtime by as much as 30%, enhancing overall efficiency. Therefore, ensure your packaging solution can accommodate your speed requirements while maintaining the flexibility for product variations.

Tips: Collaborate with your production team to gauge realistic speed requirements based on historical data and forecasts. This collaboration will ensure a more precise fit between your packaging machine and operational demands.

Budget Considerations: Cost vs. Efficiency in Packaging Solutions

When selecting a packaging machine, budget considerations are pivotal in aligning cost with efficiency. Businesses must first evaluate their specific packaging needs, which can range from production speed to the types of products being packaged. Investing in the most expensive machinery does not always translate to better performance; therefore, a detailed analysis of both initial and operational costs is essential. Understanding the long-term financial implications will help companies identify whether to prioritize upfront savings or focus on the efficiency that could yield higher productivity and lower labor costs over time.

Additionally, operational efficiency should be viewed in a broader context. A more efficient machine might demand a higher initial investment but can significantly reduce downtime and maintenance costs in the long run. Factors such as energy consumption, versatility in handling different packaging types, and ease of use also play crucial roles in determining the overall operational costs. Businesses should engage in thorough research and, if possible, conduct trials to assess the real-world performance of prospective machines. Balancing these considerations ensures that investment choices align with strategic business objectives while maintaining a healthy budget and maximizing profitability.

Analyzing Maintenance and Support Services for Packaging Machines

When selecting a packaging machine for your business, maintenance and support services are critical factors that often influence the operational efficiency and longevity of your equipment. According to a recent industry report by Research and Markets, about 70% of packaging machinery failures can be traced back to inadequate maintenance. Choosing a machine with robust support services can reduce downtime and extend the life of your equipment, leading to higher overall productivity.

Tips: Be sure to check if the manufacturer offers comprehensive training programs for your team. Proper training can minimize mishandling or misuse of the packaging machine, which is essential to prevent unnecessary wear and tear.

Additionally, accessibility to spare parts and technical support plays a significant role. A survey from Packaging Strategies revealed that companies with reliable service contracts are 40% less likely to experience major breakdowns. Having a support team that is readily available can greatly influence the speed with which any issues can be resolved, ultimately impacting your production line's efficiency.

Tips: Consider evaluating the historical performance of service providers, including customer satisfaction ratings and response times during peak operation periods. A trustworthy partner can make all the difference in maintaining seamless packaging processes.

Related Posts

-

How to Choose the Right Packaging Equipment for Your Business Needs

-

Top 10 Wrapping Machines to Boost Your Packaging Efficiency in 2023

-

10 Best Packet Machines for Efficient Packaging Solutions

-

10 Best Creative You Packaging Ideas to Enhance Your Brand Visibility

-

Top 5 Innovative Food Packaging Solutions for Sustainable Living

-

Top 10 Benefits of Using a Case Packer Machine for Your Business