How to Choose the Best Packer Machine for Your Packaging Needs in 2025

In the ever-evolving world of packaging, choosing the right packer machine is crucial for businesses aiming to streamline their operations and enhance efficiency. As we approach 2025, advancements in technology and changing consumer demands are influencing packaging techniques, making it essential for companies to carefully evaluate their options. Understanding the specific features and capabilities of various packer machines can greatly impact production speed, accuracy, and overall cost-effectiveness.

When selecting a packer machine, businesses must consider factors such as the type of products being packaged, the desired packaging format, and the scalability for future growth. Additionally, developments in automation and smart technology offer new opportunities for optimization, allowing manufacturers to improve quality control and reduce labor costs. With so many options available in the market, having a clear strategy and understanding of one’s packaging needs will be key in making an informed decision.

This guide will delve into the various aspects of packer machines, outlining the critical factors to consider when making your selection. By focusing on these essential elements, businesses can position themselves to harness the benefits of modern packaging solutions and effectively meet the demands of their customers in 2025 and beyond.

Understanding Different Types of Packer Machines Available in 2025

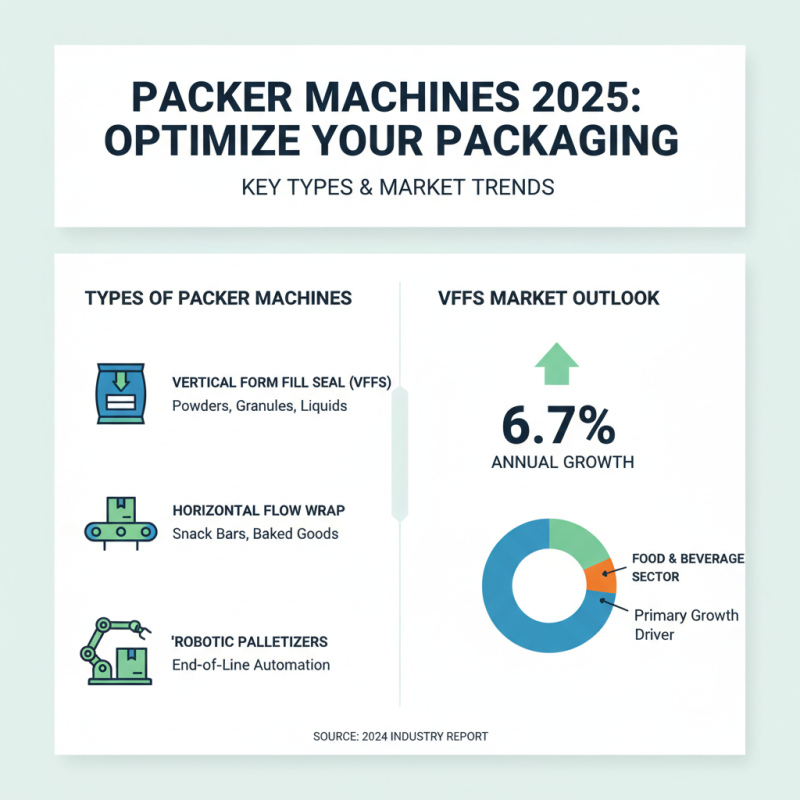

In 2025, understanding the various types of packer machines is crucial for optimizing your packaging operations. There are several categories of packer machines available, each designed for specific packaging needs. For instance, vertical form fill seal (VFFS) machines are particularly popular for packaging powders, granules, and liquids. According to a recent industry report, the VFFS market is projected to grow by 6.7% annually, driven by increasing demand in the food and beverage sector.

Another category to consider is the horizontal form fill seal (HFFS) machines, which are more suited for packaging larger items or complex packages. These machines can enhance efficiency by allowing faster packing speeds and reducing waste. Industry experts have noted that integrating automation in HFFS systems can improve accuracy and significantly minimize labor costs.

Tips: When selecting a packer machine, assess your production volume and types of products to determine which machine best fits your needs. Additionally, consider future scalability; choose equipment that can be upgraded or modified as your packaging requirements evolve. Investing in machines with smart technologies can also enhance data tracking and operational efficiency, ensuring you remain competitive in the market.

Evaluating Packaging Material Compatibility for Your Packer Machine

When choosing the best packer machine for your packaging needs, one of the most critical factors to consider is the compatibility of your packaging materials. Different materials, such as plastic, paper, glass, or metal, have unique characteristics that affect how they should be packed and processed. Understanding these properties will help ensure that the packer machine you select can handle the specific material effectively, maintaining integrity and efficiency throughout the packaging process.

Evaluate the physical and chemical properties of your packaging materials to determine their suitability for different packing machines. For instance, soft and flexible materials may require machines with adjustable sealing temperatures and pressures to prevent damage during the packing process. On the other hand, rigid materials might need a more robust setup to ensure secure sealing. Additionally, consider whether your packaging will be exposed to various environmental factors, such as moisture or temperature changes, which could influence the choice of machine components, like seals and conveyors, to accommodate these conditions.

Moreover, consider the specific requirements of your product when assessing material compatibility. For instance, food and pharmaceutical products may necessitate machines that comply with strict hygiene standards and have materials suitable for direct contact. Overall, evaluating these aspects will guide you in selecting a packer machine that not only meets your operational needs but also preserves the quality and safety of your products throughout their lifecycle.

Packaging Material Compatibility and Packer Machine Efficiency in 2025

Assessing Production Speed and Efficiency Needs in Packer Machines

When selecting the best packer machine for your packaging needs in 2025, assessing production speed and efficiency is crucial. According to a report from Smithers Pira, the global market for packing machinery is expected to grow at a CAGR of 4.6%, reaching $50 billion by 2025. This growth is primarily driven by the increasing demand for automated packaging solutions that enhance production speed. Companies are now prioritizing machines that can handle higher throughput without compromising quality, allowing them to meet the rising consumer expectations for rapid delivery and efficient service.

To effectively determine your production speed needs, consider the type of products being packaged. For instance, high-speed packer machines can process up to 400 packages per minute, ideal for mass-produced items. Conversely, slower machines catering to niche products may only need to achieve speeds of 50 packages per minute. The International Packaging Association highlights that integrating advanced technology, such as AI and IoT, can significantly improve machine efficiency by up to 30%, further optimizing production lines. This integration not only streamlines the packaging process but also reduces downtime through predictive maintenance, ensuring that operations remain smooth and uninterrupted. Choosing the right machine involves balancing speed with the specific requirements of your product line, ensuring both efficiency and quality in your packaging operations.

How to Choose the Best Packer Machine for Your Packaging Needs in 2025

| Packer Machine Type | Production Speed (Units/Min) | Efficiency Rating (%) | Power Consumption (kW) | Investment Cost ($) |

|---|---|---|---|---|

| Horizontal Packer | 120 | 85 | 5.0 | 15000 |

| Vertical Packer | 100 | 80 | 4.5 | 12000 |

| Robotic Packer | 200 | 90 | 6.5 | 25000 |

| Wrap-Around Packer | 150 | 82 | 5.5 | 18000 |

| Shrink Wrapper | 90 | 75 | 3.5 | 10000 |

Key Features to Look for in a Modern Packer Machine

When selecting the ideal packer machine for your packaging needs in 2025, it's essential to focus on key features that ensure efficiency and adaptability. One of the most critical aspects to consider is automation. According to a recent industry report, automated packing systems have witnessed a growth rate of 4.5% annually, driven by the demand for faster production lines and reduced labor costs. Machines that incorporate advanced robotics can handle various packaging formats and adjust quickly between product sizes, which is especially valuable in sectors experiencing frequent product changes.

Another vital feature is connectivity and integration capabilities. As the packaging industry increasingly embraces Industry 4.0, packer machines equipped with IoT (Internet of Things) technology are becoming a necessity. These machines can communicate with other equipment in the production line, providing real-time data on performance and contributing to predictive maintenance strategies. Reports indicate that manufacturers utilizing connected machinery can achieve up to 30% more efficient operations due to improved uptime and reduced operational costs. Moreover, flexibility in packaging materials and designs is essential as consumer preferences evolve; modern packer machines must be versatile enough to handle a range of materials while maintaining high-speed processing.

Adopting eco-friendly technologies is also gaining prominence, as sustainability becomes a central concern for consumers and companies alike. Packer machines that utilize less energy, generate minimal waste, and incorporate recyclable materials can help manufacturers align with these values. A study highlighted that sustainable packaging practices could enhance brand loyalty and consumer trust, with 72% of consumers willing to pay a premium for environmentally friendly products. Integrating these features will not only optimize your packaging process but also prepare your business for the future of sustainable manufacturing.

Cost Considerations and Budgeting for Packer Machine Investment

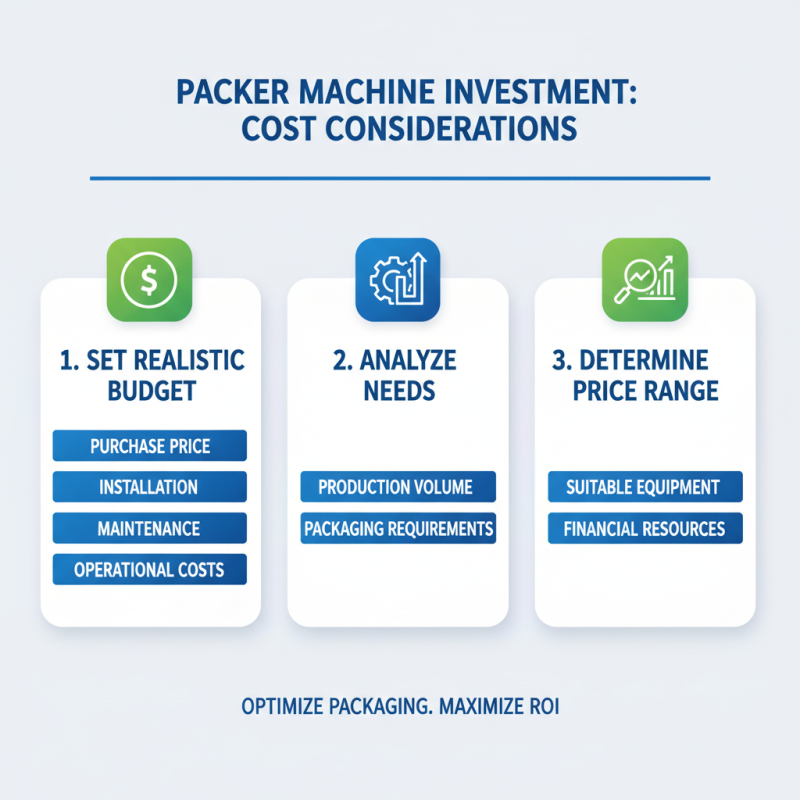

When considering the investment in a packer machine, cost considerations play a pivotal role in ensuring that your packaging needs are met without straining your financial resources. Setting a realistic budget is crucial; it should encompass not only the purchase price of the machine but also associated costs such as installation, maintenance, and operational expenses. A thorough analysis of your production volume and the specific requirements of your packaging process will help determine the most suitable price range for the equipment you need.

Moreover, exploring potential financing options or leasing arrangements can provide added flexibility and allow you to allocate funds toward enhancements or upgrades in other areas of your business. Evaluating the long-term return on investment (ROI) is essential, as a higher upfront cost for a more efficient machine could lead to lower operational costs and increased productivity over time. Keeping these factors in mind will enable you to make a well-informed decision that aligns with both your immediate budget and future growth aspirations.

Related Posts

-

Top 10 Packer Machines: Best Choices for Efficient Packaging Solutions in 2023

-

How to Choose the Right Packaging Machine for Your Business Needs

-

Why Investing in Food Packaging Equipment is Essential for Your Business Success

-

Top 10 Wrapping Machines to Boost Your Packaging Efficiency in 2023

-

How to Choose the Right Packaging Equipment for Your Business Needs

-

Top 10 Packaging Automation Equipment Trends for 2023 You Need to Know