Top 10 Benefits of Using a Case Packer Machine for Your Business

In today's fast-paced manufacturing environment, the efficiency and effectiveness of packaging processes can significantly impact a business's bottom line. As companies strive to streamline operations and reduce costs, many are turning to advanced technologies such as the case packer machine. According to John Smith, an industry expert and CEO of PackTech Solutions, "Adopting a case packer machine is not just about automation; it's about redefining productivity and ensuring product integrity." This sentiment underscores the pivotal role that case packer machines play in modern production lines.

A case packer machine offers numerous advantages that can enhance the operational capabilities of any business engaged in packaging. From minimizing labor costs to improving packing speed and accuracy, these machines are designed to handle a variety of products and accommodate different packaging formats. As we explore the top 10 benefits of using a case packer machine, it becomes clear that this investment is essential for companies looking to stay competitive in an ever-evolving market landscape.

By integrating a case packer machine into their operations, businesses can not only achieve higher efficiency levels but also ensure a more reliable and consistent packaging process. This ultimately leads to greater customer satisfaction and improved product delivery, solidifying the case packer machine's status as an indispensable asset in the packaging industry.

Understanding Case Packer Machines and Their Functionality

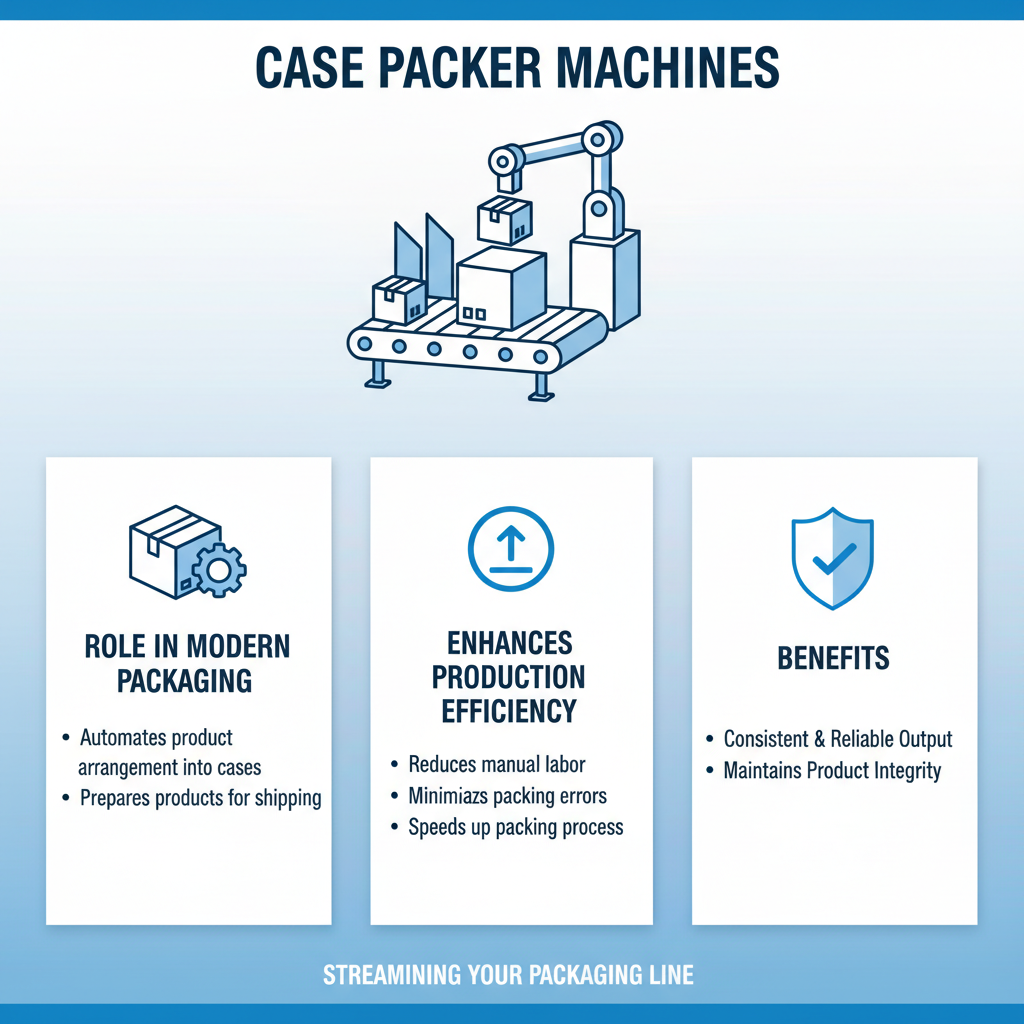

Case packer machines play a crucial role in modern packaging processes, streamlining the way products are organized and prepared for shipping. These machines automate the arrangement of products into cases or cartons, significantly enhancing efficiency in production lines. By utilizing case packer machines, businesses can reduce manual labor and minimize the risk of errors that often occur during manual packing. This automation not only speeds up the packing process but also ensures a consistent and reliable output, which is essential in maintaining product integrity.

In terms of functionality, case packer machines are designed to accommodate various types of products, from bottles to boxes, and can handle different packaging styles, such as top-loading or side-loading. Their versatility allows businesses to adapt to changing market demands and production requirements seamlessly. Additionally, advanced case packer technology can integrate with conveyor systems and inventory management software, further optimizing operations. By leveraging these machines, companies can focus on scaling their production capabilities while ensuring that their products are securely packed and ready for distribution.

Streamlining Production Processes with Case Packer Machines

Case packer machines are revolutionizing the way businesses streamline their production processes. These machines efficiently group, pack, and seal products into cases, significantly enhancing operational productivity. According to a recent report by PMMI, the Association for Packaging and Processing Technologies, companies that implement automated packaging solutions like case packers can experience a productivity increase of up to 30%. This boost is largely attributed to the reduction of labor-intensive tasks, allowing personnel to focus on more strategic roles within the organization.

In addition to increased efficiency, case packer machines also contribute to improved accuracy in packaging. Manual packing processes often lead to errors and inconsistencies, impacting product quality and customer satisfaction. Automation mitigates these risks by providing precise packing according to predefined specifications. An industry analysis by Grand View Research indicates that automating the packaging process can reduce product waste by as much as 15%.

Tip: To maximize the benefits of case packer machines, consider investing in customizable solutions that can adapt to varying product sizes and types. This flexibility not only accommodates diverse production needs but also ensures long-term viability as market demands change. Always conduct regular maintenance on your machines to maintain optimal performance and reduce downtime.

Enhancing Product Safety and Integrity Using Automated Packing

The packaging machinery industry plays a crucial role in automating and enhancing packaging processes across various sectors, including food, pharmaceuticals, and consumer goods. With technological advancements, the demand for automated packing solutions has surged, leading to heightened efficiency, improved product safety, and integrity. Automated systems are designed to minimize human error and contamination risks, ensuring that products are sealed securely and are easily traceable throughout the supply chain.

In particular, the market for pharmacy automation and vacuum packaging has demonstrated significant growth potential. The pharmacy automation market, projected to expand from about $6.4 billion in 2022 to a CAGR of 7.9% by 2032, reflects the importance of reducing contamination and prescription errors, which enhances patient safety and satisfaction. Similarly, the vacuum packaging market is expected to grow from $34.63 billion in 2024 to about $53.21 billion by 2035, with a steady growth rate of 3.98%. This trend underscores the industry's commitment to advancing technologies that not only streamline operations but also enhance the overall integrity and safety of packaged products.

Cost-Effectiveness and Labor Savings of Case Packer Machines

The implementation of case packer machines offers significant cost-effectiveness and labor savings for businesses. As automation continues to gain traction, these machines streamline packaging processes, reducing the need for manual labor. With the global market for side load case packing machines projected to reach USD 3.2 billion by 2035, businesses are increasingly recognizing the competitive edge afforded by investing in these technologies. Automation not only minimizes labor costs but also enhances production speed and accuracy, leading to improved operational efficiency.

Moreover, optimizing warehouse labor through the use of case packer machines allows businesses to allocate resources more effectively. By embracing advanced packaging solutions, companies can reduce workforce strain while increasing output. This shift not only supports better labor management but also positions businesses to adapt quickly in an unpredictable market. As organizations explore innovative packaging technologies, the long-term benefits of cost reduction and increased productivity become apparent, further driving the shift towards automation in the industry.

Top 10 Benefits of Using a Case Packer Machine for Your Business

| Benefit | Description | Potential Savings |

|---|---|---|

| Cost Reduction | Using case packers reduces manual labor costs significantly. | Up to 30% in labor costs |

| Increased Efficiency | Automated packing speeds up the process compared to manual methods. | 50% faster packing times |

| Consistency | Provides uniform packing, reducing errors and waste. | Minimized packing waste by 25% |

| Flexibility | Can be used for various box sizes and product types. | Versatile application increases market reach |

| Improved Safety | Reduces the risk of injury associated with manual packing. | Lower injury-related costs |

| Space Efficiency | Optimized machinery footprint versus manual packing stations. | Potential to save up to 20% floor space |

| Reduced Labor Dependence | Less reliance on variable labor force for packing tasks. | Stable workforce costs |

| Faster ROI | Quicker returns on investment due to cost savings and efficiencies. | Return within 1-2 years |

| Enhanced Product Handling | Gentler handling of products reduces damage. | Decreased damage costs by 15% |

| Scalability | Easily adjustable for growing production needs. | Supports business growth effectively |

Improving Operational Efficiency and Reducing Error Rates

Implementing a case packer machine can significantly enhance operational efficiency in your business. These machines streamline the packing process, allowing products to be efficiently packed into cases with minimal human intervention. By automating this critical task, businesses can respond more swiftly to demand fluctuations while maintaining consistent packing quality. This reduction in manual labor not only speeds up fulfillment times but also minimizes the likelihood of human errors, contributing to a more reliable packaging operation.

Tip: When introducing a case packer machine, ensure that your staff is trained adequately to operate and maintain the equipment. This will help in maximizing the machine's performance and longevity.

In addition to boosting efficiency, case packer machines help reduce error rates in order fulfillment. Traditional packing methods often involve repetitive manual tasks that can lead to mistakes, such as incorrect case counts or improper packing. A case packer machine consistently applies the same packing standards, resulting in higher accuracy and less waste. This reliability can build customer trust and satisfaction, as they receive their orders exactly as expected.

Tip: Regularly monitor the packing process and gather data on error rates. This will enable you to identify improvement areas and gauge the impact of the case packer machine on overall operational performance.

Top 10 Benefits of Using a Case Packer Machine

Related Posts

-

Top 10 Wrapping Machines to Boost Your Packaging Efficiency in 2023

-

10 Best Creative You Packaging Ideas to Enhance Your Brand Visibility

-

7 Essential Tips for Optimizing Packaging Systems: Boost Efficiency by 30%!

-

10 Best Packet Machines for Efficient Packaging Solutions

-

Top 10 Packer Machines: Best Choices for Efficient Packaging Solutions in 2023

-

Top 5 Innovative Food Packaging Solutions for Sustainable Living