2025 Guide: How to Choose the Best Pouching Machine for Your Needs

As the packaging industry continues to evolve, the demand for efficient and versatile pouching machines has surged. According to a recent report by Smithers Pira, the global market for pouch packaging is expected to reach $46.2 billion by 2025, driven by the growing need for convenient and sustainable packaging solutions. This trend underscores the importance of selecting the right pouching machine that caters to specific production needs and operational requirements.

Industry expert Dr. Emily Harper, a noted authority on packaging machinery, emphasizes the significance of making informed decisions in this domain. She states, "The right pouching machine not only enhances productivity but also aligns with the sustainability goals of modern enterprises." Such insights highlight the necessity for businesses to assess various factors, including speed, efficiency, machine capabilities, and adaptability, when choosing a pouching machine for their operations. As companies across various sectors aim to optimize their packaging processes, understanding the nuances of pouching machines becomes critical in achieving long-term success.

Understanding Pouching Machines: Types and Functions

Understanding pouching machines is essential for any business looking to improve packaging efficiency. These machines are primarily classified into three main types: vertical form fill seal (VFFS), horizontal form fill seal (HFFS), and pre-made pouch fill seal machines. VFFS machines are often favored for high-speed packing needs, as they can quickly convert a roll of film into pouches. According to a recent industry report, the market for VFFS machines is expected to grow at a CAGR of 5.6% from 2023 to 2030, driven by advancements in automation and an increasing demand for ready-to-eat food products.

HFFS machines, on the other hand, excel in packaging products that require more complex handling, such as delicate items or fragile pellets. They provide a higher level of aesthetic and functional customization compared to their vertical counterparts. Furthermore, pre-made pouch machines are gaining traction due to their flexibility; they can accommodate various pouch styles, such as stand-up pouches or zip-lock bags, allowing for greater versatility in product offerings. A study by Grand View Research indicates a notable shift towards pre-made pouch technology, with a projected increase in usage across sectors like food, pharmaceuticals, and personal care.

Tips: When selecting a pouching machine, consider the nature of your product—its size, weight, and fragility—as these factors significantly influence machine compatibility. Additionally, evaluate your production volume requirements to ensure the machine can meet your pace without compromising quality. Always prioritize machines that offer easy changeover and adjustments to minimize downtime during production runs.

Key Factors to Consider When Choosing a Pouching Machine

When choosing the best pouching machine for your needs, several key factors must be considered to ensure optimal efficiency and quality. First and foremost, assess your production volume. You'll need a machine that can handle your specific output requirements without compromising speed or precision. For larger operations, machines with higher capacities and automated features can significantly reduce labor costs and improve productivity.

Another important factor is the type of materials you'll be using. Different pouching machines are designed for various materials, including flexible films, laminates, and foils. Choosing a machine that accommodates the specific characteristics of your packaging materials will enhance the quality of the finished product and minimize production issues.

Assessing Your Production Needs and Capacity Requirements

When choosing the best pouching machine for your production needs, assessing

your production capacity is crucial. Start by evaluating the volume of products you intend to package on a daily,

weekly, or monthly basis. This information will provide insight into the machine’s speed and output requirements.

For example, if your operation demands high-volume output, selecting a machine that can handle rapid packing rates

while maintaining consistency and quality is essential. Additionally, understanding your product

characteristics, such as size and weight, will help narrow down your options, ensuring the chosen machine can

accommodate your items without compromising efficiency.

Another important factor is the flexibility of the pouching machine in managing various packaging formats. If

your production needs might change, selecting a machine with adjustable settings for

different pouch sizes and styles can enhance adaptability. Moreover, consider the ease of integration with existing production lines

and the level of automation required. Machines that align well with your operational workflow can boost overall efficiency,

reduce downtime, and minimize labor costs. By taking the time to assess your production needs and capacity requirements,

you can confidently choose a pouching machine that aligns perfectly with your business goals.

Evaluating Budget Constraints and Cost-Effectiveness

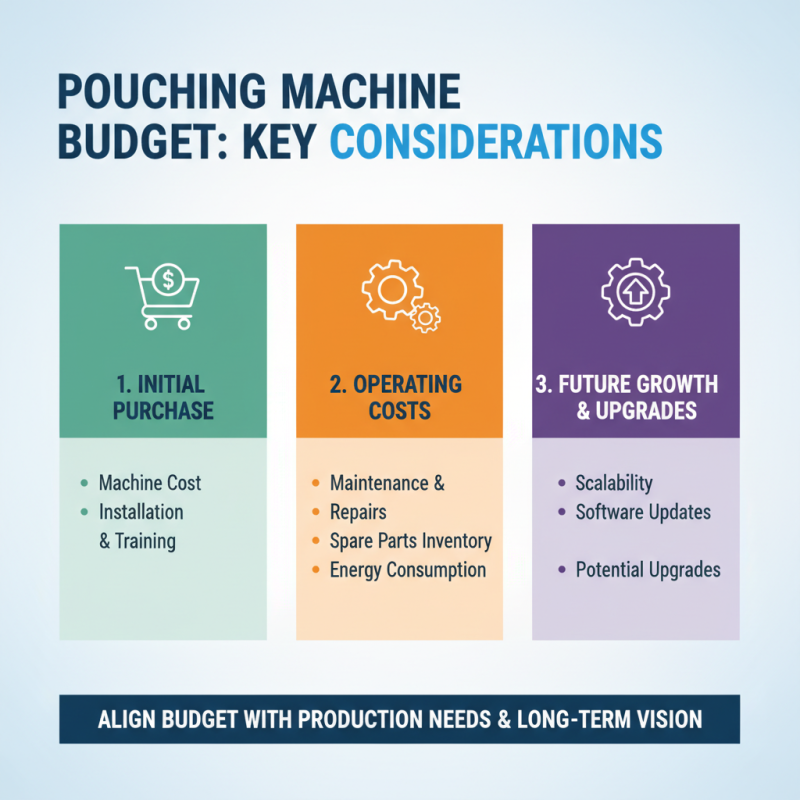

When considering the purchase of a pouching machine, budget constraints play a pivotal role in the decision-making process. Before diving into specific features or capacities, it's essential to establish a clear budget that aligns with your production needs and financial capabilities. This involves evaluating not only the initial purchase cost but also the long-term expenses, including maintenance, spare parts, and potential upgrades. A well-thought-out budget ensures that you can invest in a machine that not only meets your current demands but also accommodates future growth without straining your finances.

Moreover, the concept of cost-effectiveness is crucial when selecting a pouching machine. It's important to analyze the return on investment (ROI) associated with different models. A more expensive machine might offer advanced features and greater efficiency, resulting in lower operating costs and higher output in the long run. Conversely, a lower-priced option may seem attractive initially but could lead to higher costs in repairs and downtime. Conducting a thorough cost-benefit analysis helps in identifying the machine that will provide the best value for your investment while considering both immediate and future operational needs.

Maintenance and Support: What to Look For in a Supplier

When selecting a pouching machine, one of the most critical factors to consider is the level of maintenance and support offered by the supplier. An effective supplier should provide comprehensive maintenance services that ensure your equipment operates smoothly and efficiently. Look for suppliers who offer regular servicing schedules and quick response times to address any issues that may arise. A well-structured maintenance plan not only prolongs the lifespan of your machine but also minimizes downtime, which is vital for maintaining productivity in a fast-paced environment.

In addition to maintenance, the availability of reliable technical support is essential. A knowledgeable support team can provide immediate troubleshooting assistance, reducing the time spent on resolving issues. Ensure that the supplier offers various channels for support, such as phone, email, or live chat, enabling you to contact them easily whenever you need help. It’s also beneficial to consider suppliers that provide extensive training and resources for your staff, allowing them to handle basic maintenance and operational issues independently while building their confidence in using the machine effectively. Investing time in evaluating these aspects of supplier support will pay off in the long run, ensuring you choose a pouching machine that meets your needs without compromising on service quality.

Pouching Machine Features Comparison

Related Posts

-

10 Best Creative You Packaging Ideas to Enhance Your Brand Visibility

-

7 Essential Tips for Optimizing Packaging Systems: Boost Efficiency by 30%!

-

How to Choose the Right Case Packer Machine for Your Packaging Needs

-

Top 5 Innovative Food Packaging Solutions for Sustainable Living

-

10 Best Packet Machines for Efficient Packaging Solutions

-

Top 10 Wrapping Machines to Boost Your Packaging Efficiency in 2023